Description

034Motorsport is proud to introduce Density Line Performance Engine/Transmission Mounts for Volkswagen & Audi MQB and MQB EVO vehicles equipped with the 2.0T TFSI! 034Motorsport's Street Density Mounts for MQB and MQB EVO platform vehicles deliver unmatched levels of comfort and performance.

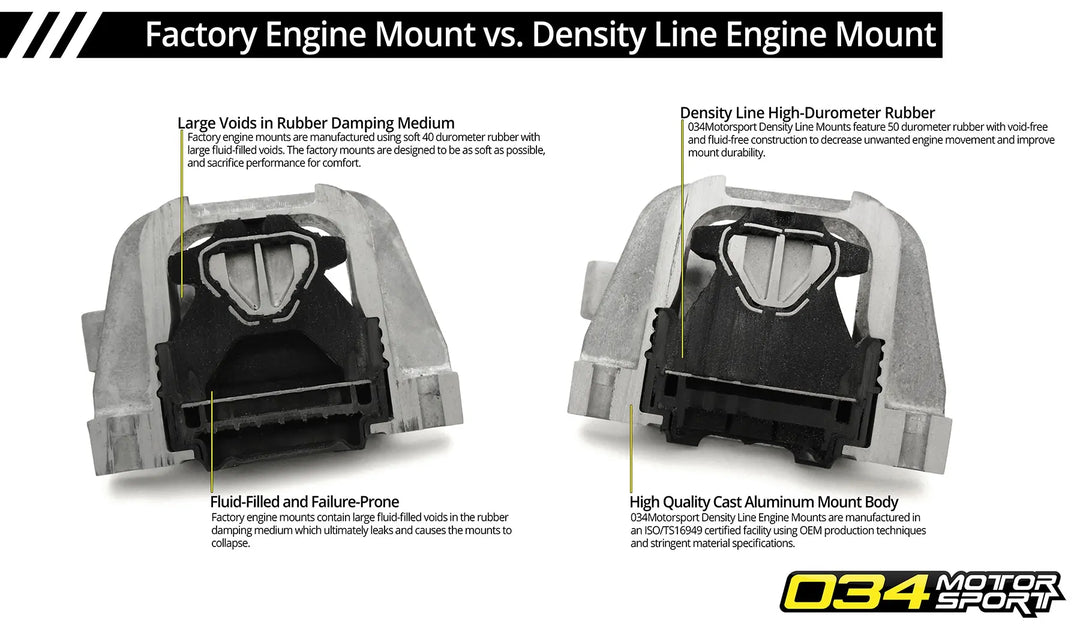

Density Line Drivetrain Mounts are engineered with performance in mind, and provide an OEM+ driving experience without sacrificing comfort. Density Line Mounts are fluid-free, and manufactured from high-durometer rubber to significantly improve performance and longevity over factory mounts. By eliminating the slop associated with the stock mounts, the Density Line Mounts reduce wheel hop, improve response, and offer a more direct, connected driving experience.

Street Density:

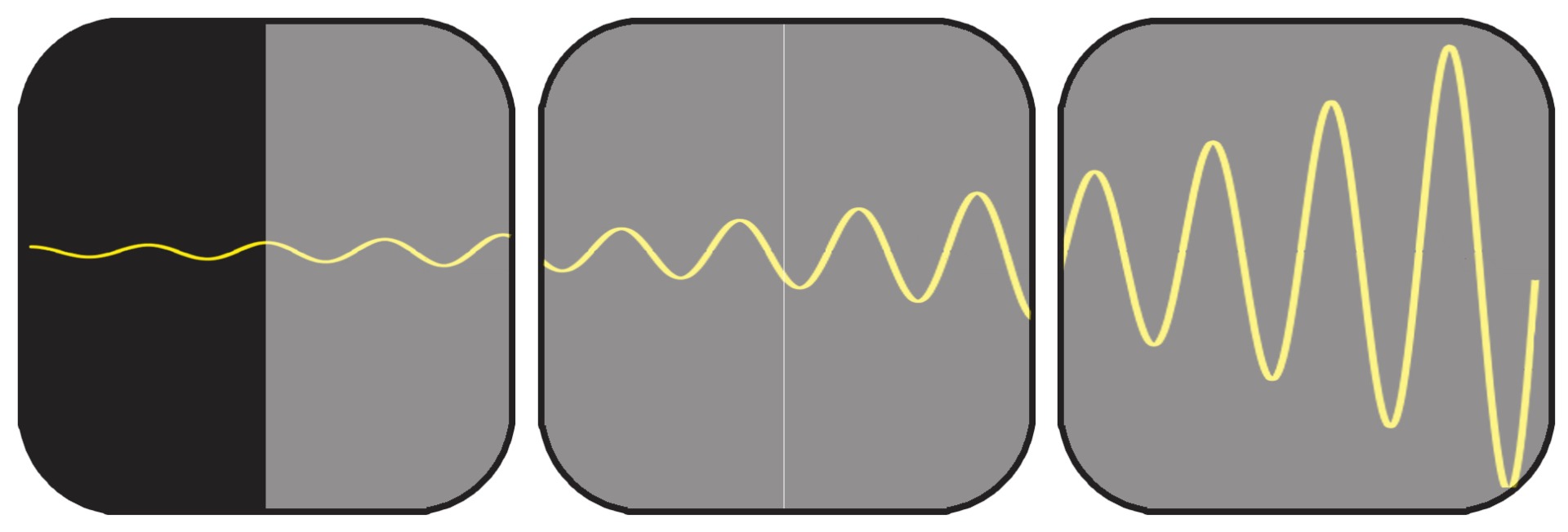

The Street Density Engine Mount Pair is manufactured from 50 durometer and 60 durometer rubber, which is approximately 25% stiffer than stock. Since the mounts are also solid-filled, the result is a substantial reduction in drivetrain movement versus the factory mounts.

The result is greatly reduced drivetrain slop, crisper shifting, and minimal wheel hop, without any significant increase in noise, vibration, or harshness (NVH) inside of the cabin. These mounts are a completely re-engineered performance solution, not just inserts for use with the factory mounts.

Features:

- Manufactured from 50 Durometer & 60 Durometer (Street Density) Rubber with Fluid-Free Construction

- Reduced Drivetrain Slop

- Decreased Engine Movement Under Load

- More Direct Power Transfer

- Improved Shifting Feel

- Complete Drop-In Replacement of Factory Engine/Transmission Mounts

- Sold in Pairs (One Engine Mount & One Transmission Mount)

High-Durometer Rubber vs. Polyurethane:

Density Line Mounts are manufactured from high-durometer rubber instead of polyurethane for a number of reasons. While vulcanized rubber mounts are more expensive to prototype due to increased complexity of manufacturing and high initial tooling costs, rubber is inherently better than polyurethane as a damping medium for mounts and bushings.

Rubber is able to deal with stress under both tension and compression, while polyurethane mounts rely on the damping medium to be effective only under compression. Rubber is also excellent in shear, where polyurethane is ineffective, making it ideal for control arm bushings that apply a shear force to the bushing during articulation.

Rubber does not pack and wear as quickly polyurethane does, which ultimately results in a longer-lasting part with consistent performance and comfort.

NOTE: This Street Density Mount application features stiffer and less compliant rubber, however, the mount is not designed to see significantly larger amounts of abuse, as Density Mounts use a similar design and construction to the OEM mounts. This means that driving dynamics are improved, but these mounts are not necessarily suited for more punishing applications or abuse. Normal "sport driving" will typically see these mounts lasting up to 50k miles or more. More abusive use, such as aggressive drag racing, clutch dumps, aggressive shifting, and big increases in power, can cause these mounts to fail or wear prematurely, typically in 20k miles or less. For mounts that will sustain the latter abusive scenarios, we strongly recommend our Motorsport Mounts which are designed for specifically for such use.